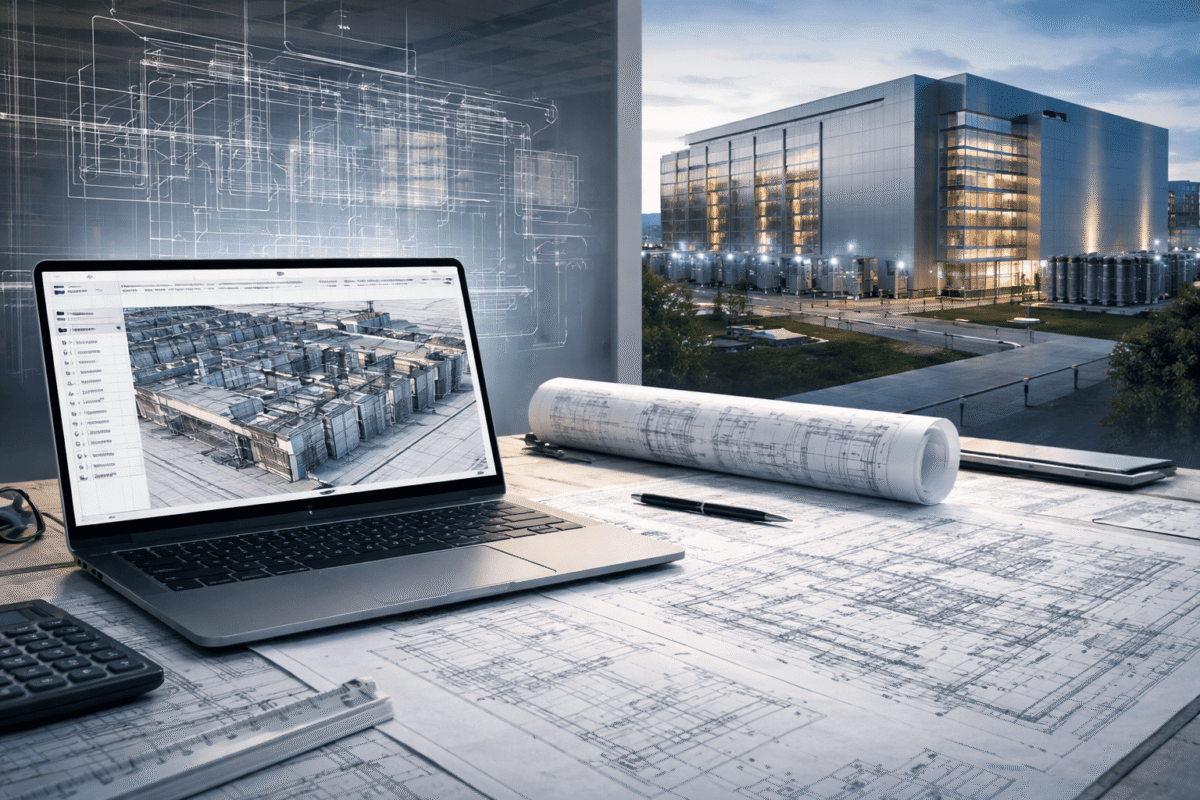

You wouldn’t perhaps deny that the rapid advancement of artificial intelligence is indeed rewriting the rules around digital infrastructure. As AI workloads become more pervasive and intensive, the need for hyper-effective, adaptable data centers is growing rapidly.

The United States itself is witnessing an all-time data center construction boom. In fact, AI demand has driven capital deployment to a record $31.5 billion in 2024. By the end of September 2025, this figure reached $40 billion, according to Reuters.

However, for AEC firms in the country, this investment wave leads to an enormous volume of mission-critical tasks. As a matter of fact, they are now on the verge of a defining opportunity in this fast-growing infrastructure market.

What is more crucial to understand is that this level of growth pushes AEC firms’ internal production capacity to its limits. Conventional in-house production teams generally struggle with keeping pace with this surge in complex, time-sensitive documentation. AEC businesses that respond with scalable, offshore architectural production will pioneer this segment.

The Surge in AI-Powered Data Center Construction

Just last year, the megacap technology companies announced a collaborative investment of over $300 billion behind developing AI infrastructure. At the beginning of 2025, the US data center market was valued at over $48 billion and is expected to reach approximately $112 billion by the end of 2029.

Keep in mind that this is not a short-term spike. AI data center construction currently reshapes the US built environment at a structural level. Every single project operates at an extraordinary scale. AI giants have big plans to further strengthen their data infrastructure by building new data centers.

From a strict AEC perspective, each of these facilities needs thorough architectural construction documents, detailed code compliance, and multidisciplinary coordination. That’s why US-based AEC firms should keep pace with hyperscaler investment and build production capacity.

What AI Data Center Projects Need from AEC Firms

It is true that AI data centers are among the most technically complicated building types in contemporary construction. A report from the International Energy Agency reveals that a standard AI data center uses approximately as much electricity as 100,000 households. Large-scale data centers can consume as much as 5 million gallons of water per day. These operational realities leave no room for error in maintaining documentation accuracy across every engineering discipline.

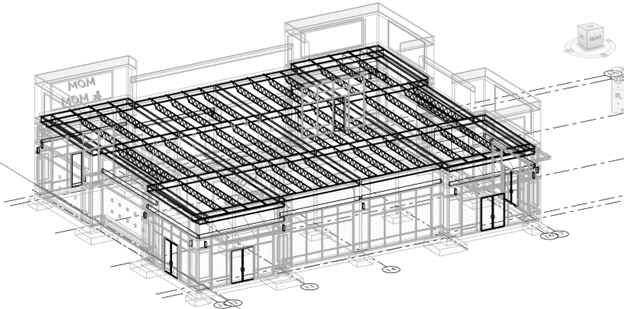

Critical technical components that data center CD sets should comprehensively address:

- Structural systems must accommodate dense server rack loads and heavy, specialized mechanical equipment on upper floors.

- Electrical infrastructure mandates precise load calculations, documented emergency power systems, and redundant switchgear layouts.

- Mechanical design should fully integrate cutting-edge liquid cooling, air handling units, and heat rejection systems.

- Life safety and ADA compliance documentation must fulfill IBC standards from the earliest design stage.

- Multidisciplinary coordination calls for consistent Revit-based models and active clash detection throughout all design trades.

Remember that each deliverable across disciplines needs detailed code verification before submitting for a permit. Any error in the construction documentation will result in expensive rework, delaying projects. Clearly, this puts AEC firms in a position where they must have the capability to master the complexity of documentation to guarantee their competitive edge in the AI data center market.

Phase-Wise CD Production and the Data Center Timeline

Every single data center construction is subject to aggressive timelines. The owner companies of these data centers set delivery deadlines that compress common project schedules considerably. To ensure everything is on the right track, AEC firms need to develop fully coordinated CD packages in defined phases. These phases involve schematic design, design development, construction documents, and final submission. Here, it is important to consider that documentation errors increase rapidly in the absence of disciplined production monitoring from the beginning.

The path to successful phase-based CD production necessitates dedicated team management from day one. US-licensed senior architects have a big responsibility here. They are required to set clear design intent, standards, and code baselines for each deliverable. Design professionals should then execute and coordinate drawings at every phase milestone. There must also be proper quality assurance reviews at each phase to catch coordination clashes early and prevent them from escalating into costly site issues. Project coordinators must provide weekly status updates to keep project managers fully informed across the entire CD production process.

Offshore architectural production has emerged as the ideal support service to address such production challenges for AEC firms. There will be a structured remote team managing the full CD workflow. Regional US representatives will be there to tackle client communication during general business hours. However, the client’s architecture of record will have the full professional responsibility and signing authority. Evidently, this CD production framework compresses timeframes while sustaining AIA-standard documentation quality until the project’s completion.

Sustainability Challenges and AEC Firms’ Design Responses

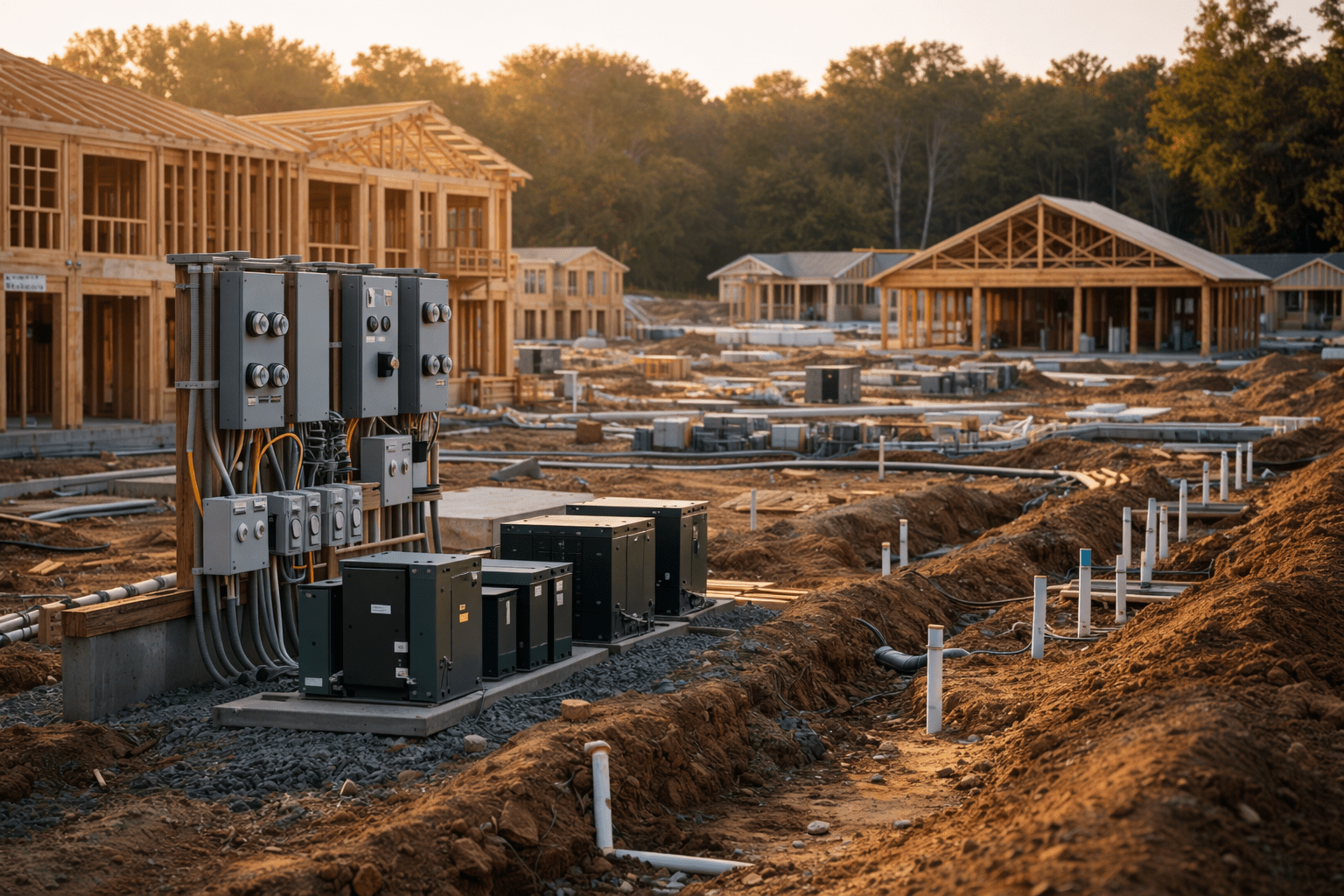

It’s also crucial to recognize that AI-ready data centers require significantly higher power and cooling than typical facilities. Many new buildings should accommodate liquid-ready cooling infrastructure, high-density racks, and complex electrical distribution topologies. This contributes to pressure on architectural layouts, MEP coordination zones, and structural grids to sync with heavy equipment and service routes. So, design teams need to iterate quickly, respond to frequent program changes, and still create coordinated construction documentation promptly.

Undoubtedly, AI data centers carry a serious and significant environmental footprint. Keeping in mind the abundant electricity and water consumption by data centers, architectural design choices are at the core of the sustainability debate. From building siting and structural orientation to MEP integration, all impact a data center’s long-term environmental footprint. This is precisely where AOP-driven phase-based CD production support becomes even more crucial for AEC firms.

This approach has proven to integrate MEP coordination from schematic design onward to help AEC firms overcome sustainability challenges proactively. A recent study clarifies that a combination of efficient siting and grid carbonization can cut carbon emissions by over 70% while reducing water consumption by around 80%. US AEC businesses that embed these considerations into early-stage documentation can deliver quantifiably better value to data center clients.

Scaling Production Without Increasing Overhead

At this current moment in the US, AEC companies are facing a clear capacity challenge. Rising labor expenses and compressed schedules are the primary two reasons behind AEC firms finding it difficult to scale in-house capacity. With a data center construction project in hand, this challenge further multiplies. Because of this, offshore architectural production support seems even more vital, as it offers a methodical, scalable solution that AEC firms are now actively pursuing.

The main benefits that offshore architectural production provides for data center CD work are:

- A dedicated remote production team that boosts an AEC firm’s capacity immediately without increasing the permanent headcount.

- US-licensed architects establish a project’s design standards, guaranteeing each CD package satisfies regional code requirements and AOR specifications.

- Phase-wise multi-layer quality assurance reviews help spot errors in coordination, compliance, and drawing consistency ahead of submission.

- A time zone advantage that keeps production running overnight, explicitly speeding up data center project delivery.

- Adjustable team structures that enable AEC firms to scale production capacity with changes in project volume.

We can confidently say that architectural offshore production is currently the key differentiator for AEC firms competing in the AI data center construction market.

Final Notes

So, the construction boom in AI data centers comes with the largest infrastructure opportunity for AEC businesses operating in the United States. The main requirements of these kinds of projects include accurate, code-adherent, coordinated construction documents on time. It is clear that in-house capacity alone cannot deal with this volume and complexity. If your AEC business has the right production infrastructure, then it can lead the data center design work for years to come.

Uppteam’s architectural offshore production services offer US-based AEC firms a direct path to code-validated, scalable CD production. We deliver fully coordinated packages of schematic design through permit-ready final submission. Our architectural production team, working remotely, is committed to ensuring each deliverable is in alignment with the rigorous technical requirements of AI data center projects.

Contact Uppteam today and start building the production capacity that this market demands.