What distinguishes permit-ready MEP drawings from expensive project delays and regulatory disapprovals? There are still architectural firms and general contractors who wonder why some of their MEP sets stall permit approvals.

A permit-ready MEP drawing set is way beyond just aesthetic polish. It is documentation made in such a way that it passes regulatory scrutiny. The present construction spectrum is highly competitive. Within this environment, architects and general contractors often encounter escalating demands for compliant documentation that fulfills stringent Authority Having Jurisdiction criteria across the U.S.

These days, authorities demand drawings with clearly highlighted HVAC zoning, electrical services, plumbing risers, equipment schedules, and code-adherent annotations. So, it is clear that contemporary building codes call for several critical elements. They mandate accurate coordination, holistic technical specifications, and error-free system integration that are more than basic schematic layouts.

When permit reviewers detect inconsistent calculations or ambiguous layouts, they call for corrections. The consequence is that projects get delayed. This makes architects and general contractors rely on MEP drawing prowess to meet occupancy deadlines and avoid rework.

This article will outline the essential elements that delineate a permit-ready MEP package and its importance in the current construction landscape.

What Exactly are the MEP Permit Requirements

Approval-ready MEP drawing sets ought to demonstrate holistic compliance with regional building codes and national guidelines. AHJs utilize some fundamental requirements to examine submitted documentation. These requirements consist of the International Building Code, National Electrical Code, and International Mechanical Code. The produced MEP drawings act as legal documents that authenticate system safety, operational efficacy, and regulatory conformance throughout the construction stages.

A comprehensive permit application should comprise specifications, equipment schedules, and calculation packages that signify system performance and regulatory compliance. It is also crucial to mention that building departments pursue multidisciplinary reviews. They include mechanical, electrical, plumbing, and structural experts who assess diverse aspects of proposed designs.

Key Documentation Elements

Permit-ready MEP drawings need to have particular technical items that AHJs want for approval. These elements include:

- Detailed equipment schedules with manufacturer specifications and performance ratings.

- Complete load calculations, showcasing ideal system capacity and safety margins.

- Thorough routing diagrams portray spatial coordination among all building systems.

- Code conformance documentation with reference to applicable standards and regional amendments.

- Integration plans represent coordination with fire protection and life safety systems.

Each of these components guarantees that reviewing authorities can authenticate system adequacy and regulatory conformance during permit assessment procedures.

Code-Conformant Framework

Contemporary AHJ approval processes have changed quite a bit. They now demand rigid compliance with several regulatory frameworks that govern MEP system design and installation standards.

A key factor to mention in this regard is that the International Energy Conservation Code explicitly influences HVAC equipment selection. It impacts system performance specifications as well. These prerequisites affect equipment efficiency ratings, insulation values, and renewable energy incorporation norms.

On the other hand, there are the National Fire Protection Association codes. They regulate the integration of fire protection systems, needing coordination among sprinkler systems, smoke detection, and emergency ventilation systems. ASHRAE Standard 90.1 offers the foundation for commercial building energy performance. It informs about the minimum efficiency requirements for HVAC systems, lighting, and building envelope elements.

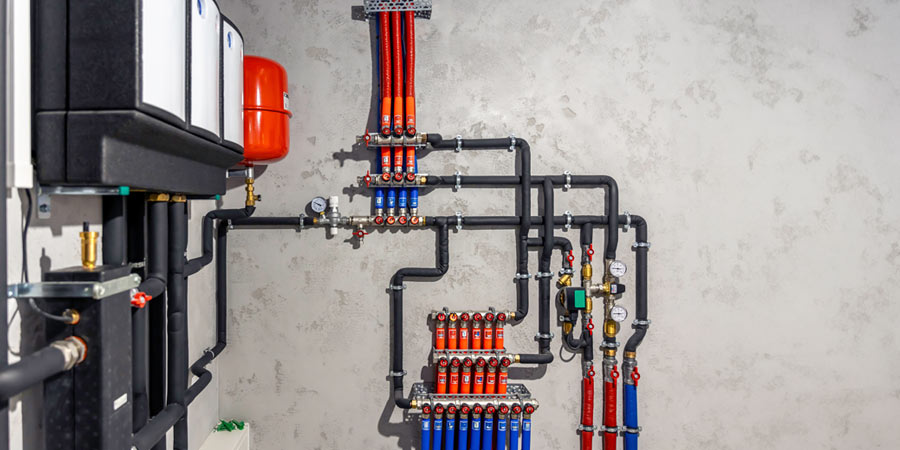

Mechanical System Documentation

It is of greatest importance for mechanical drawings to demonstrate all-encompassing system integration and performance verification for permit approvals. They need to be in alignment with ASHRAE standards and regional climate conditions. Besides, HVAC load calculations should confirm equipment sizing on the basis of envelope performance, building occupancy, and operational requirements. Another critical factor here is manufacturer specifications bespeaking energy efficacy compliance and operational reliability. This factor is of profound significance when it comes to equipment schedules.

On the contrary, there are the ductwork layouts. They should denote routing, sizing, and connection details for every zone while exemplifying sufficient accessibility and clearances for maintenance tasks. Additionally, ventilation requirements need to be in line with indoor air quality standards and code minimums for varied occupancy classifications. Finally, mechanical system documentation also requires effective integration with fire protection systems. It necessitates coordination between emergency ventilation protocols and smoke management systems.

Electrical System Requirements

Regarding electrical drawings, there should be a robust illustration of power distribution and safety system integration. This aspect is critical to permit approval.

- Diagrams of power distribution have to showcase service entrance configurations and panel schedules.

- Branch circuit layouts must involve ideal overcurrent protection and grounding systems.

- Photometric calculations need to be part of the lighting layout, demonstrating sufficient illumination levels.

- The integration of the emergency power system is required to portray backup energy capabilities and transfer switching.

- The fire alarm and telecommunications infrastructure ought to be coordinated with the building systems.

The above-mentioned components make sure that electrical systems satisfy NEC standards. However, there should be no compromise in terms of offering adequate capacity for projected building operations.

Plumbing and Fire Protection Integration

Precise water supply calculations are necessary for plumbing system documentation. Drainage system layouts and fixture schedules fulfilling local health codes and water conservation norms must also be taken into account within plumbing system documentation. It is also obligatory for the water supply systems to exhibit adequate pressure and flow rates for all fixtures. Simultaneously, the incorporation of backflow prevention and cross-connection control measures should be prioritized.

Waste and vent systems should also be on point. They require accurate isometric drawings that show appropriate sizing and slope requirements. Another vital aspect of this provision is that fire protection systems demand perfect coordination with structural and architectural components. This is to ensure ideal coverage and accessibility for maintenance operations.

Sprinkler layouts should show appropriate spacing, enough water supply, and connection to the alarm system. These drawings need spot-on hydraulic calculations that verify system performance and signify NFPA compliance for distinct occupancy classifications.

Processes of Quality Assurance and Review

Complete quality control means ensuring permit-ready drawing precision and regulatory adherence. It involves:

- Reviewing multi-disciplinary design to validate system coordination and code conformity.

- Verifying calculations to confirm equipment sizing and performance specifications.

- Checking the accuracy of the drawing to affirm dimensional consistency and specification clarity.

- Auditing code compliance to authenticate adherence to applicable standards and local norms.

- Scrutinizing constructability to certify on-site installation feasibility and construction sequencing.

These procedures are of great value. They can shorten permit review cycles and aid efficient approval procedures that uphold project schedules.

Integration of Cutting-Edge Technology

Contemporary MEP drawing creation capitalizes on BIM platforms that sustain comprehensive design coordination and documentation precision. 3D design coordination helps prevent conflicts and maintains accurate construction takeoffs and construction planning processes. These tools come with an integration of calculation software, checking code compliance, and automated drawing generation, guaranteeing consistency across all verticals.

A more interesting fact to comprehend is that cloud-based collaboration platforms allow for live design coordination among different stakeholders. They ultimately support effective review cycles and sanction processes. Furthermore, version control systems ensure that all stakeholders work with the latest drawings and specifications. The purpose here is to stay away from costly on-site conflicts and change orders at the time of executing construction work.

Energy Modeling and Sustainability Adherence

In recent times, it has been observed that MEP drawing sets’ permit approval processes need energy modeling. They must demonstrate standards associated with building performance and sustainability compliance.

Validating HVAC system effectiveness, building envelope performance, and renewable energy integration is a big part of energy calculations. These evaluations are there to support state-specific energy codes. It is vital to acknowledge that adhering to these codes is compulsory for performance verification and lasting operational efficiency.

Lastly, sustainable design documentation needs to illustrate a few crucial aspects—from water conservation measures to indoor environmental quality provisions and energy-conscious system selections. All of them should be aligned with green building certification requirements.

Final Views

So, permit-ready MEP drawing sets are indeed the cornerstone of successful project delivery. This is even more relevant concerning today’s complex regulatory atmosphere throughout the United States.

Therefore, when your next project needs permit-ready MEP drawings satisfying stringent AHJ norms, there is no better option than NationalMEPEngineers. We deliver the technical expertise and holistic documentation standards that GCs and architects can rely on to ensure a successful project outcome.

Specializing in code-compliant MEP design services, our experienced team expertly streamlines approval processes and aids prompt project delivery. However, in this course, NationalMEPEngineers never compromises on comprehensive compliance with every applicable code and standard. Visit our website and explore how our high-quality MEP services quicken the permit approval process while sustaining the optimal standards for technical precision and regulatory compliance.