A few years ago, a sudden cloudburst flooded parts of Dallas. A local structural company was receiving calls from multiple clients simultaneously. Underground garages filled up, elevator pits overflowed, and podium decks stayed damp long after the skies cleared. One senior designer reportedly said, “We designed for the structure. The storm redesigned the loads.”

That line could sum up the new normal for urban infrastructure.

Across U.S. cities, structural engineers are facing a reality where their work no longer ends with gravity and lateral loads. Stormwater — once squarely in the civil engineer’s domain — now defines how structures age, perform, and survive. The dividing line between “stormwater design” and “structural design” is blurring fast.

As Harshal Doshi, Senior Structural Designer at Uppteam, puts it, “We used to think of water as something that happens around a building. Now we see it as something that happens through it.”

Why Structures Are Now Part of the Stormwater Story

The shift didn’t happen overnight. Cities like Miami, Houston, and New York have seen record-breaking rainfalls in the past decade. Codes have caught up—slowly—but most of the infrastructure was built for a climate that no longer exists.

The result? Structures now experience load conditions and exposure cycles they were never meant to endure. Below-grade garages stay humid, rebar corrosion accelerates, slabs deflect under ponding loads, and drainage systems overwhelm the very structures that house them.

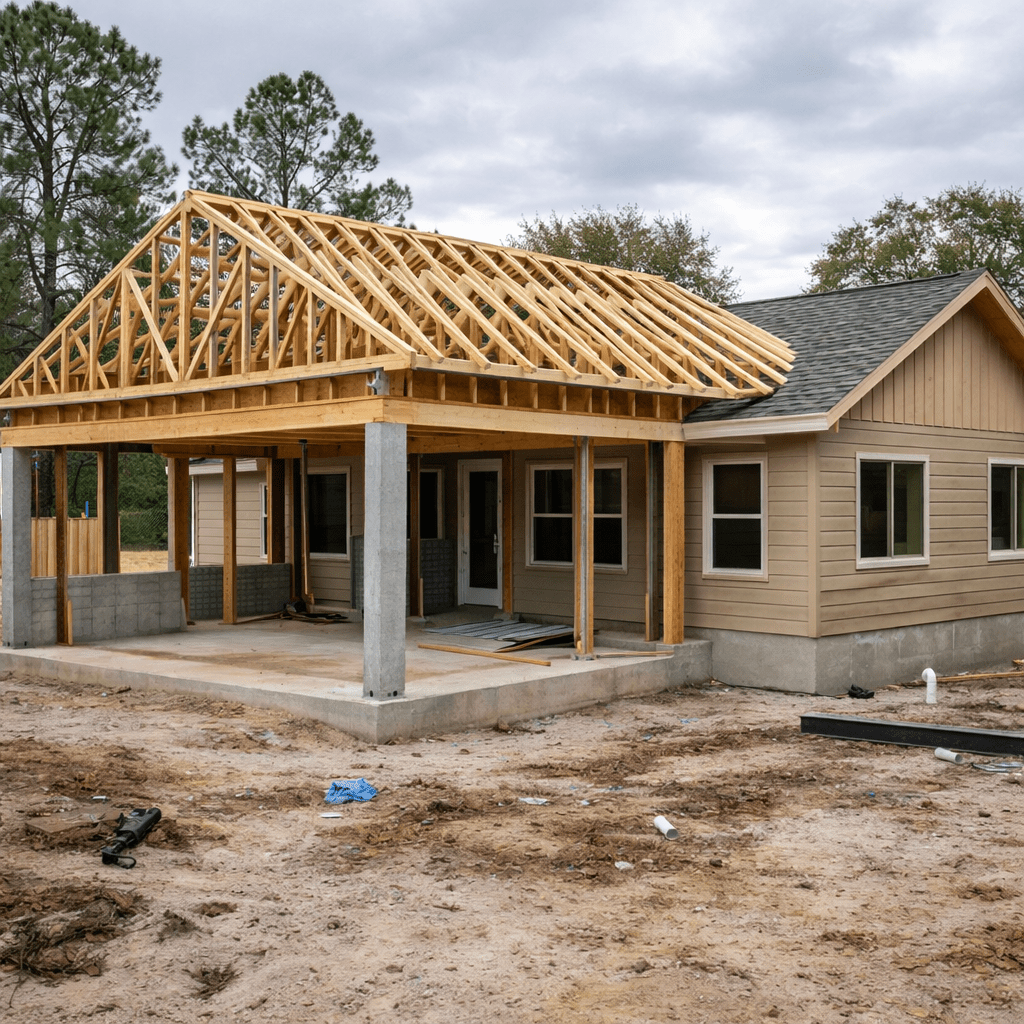

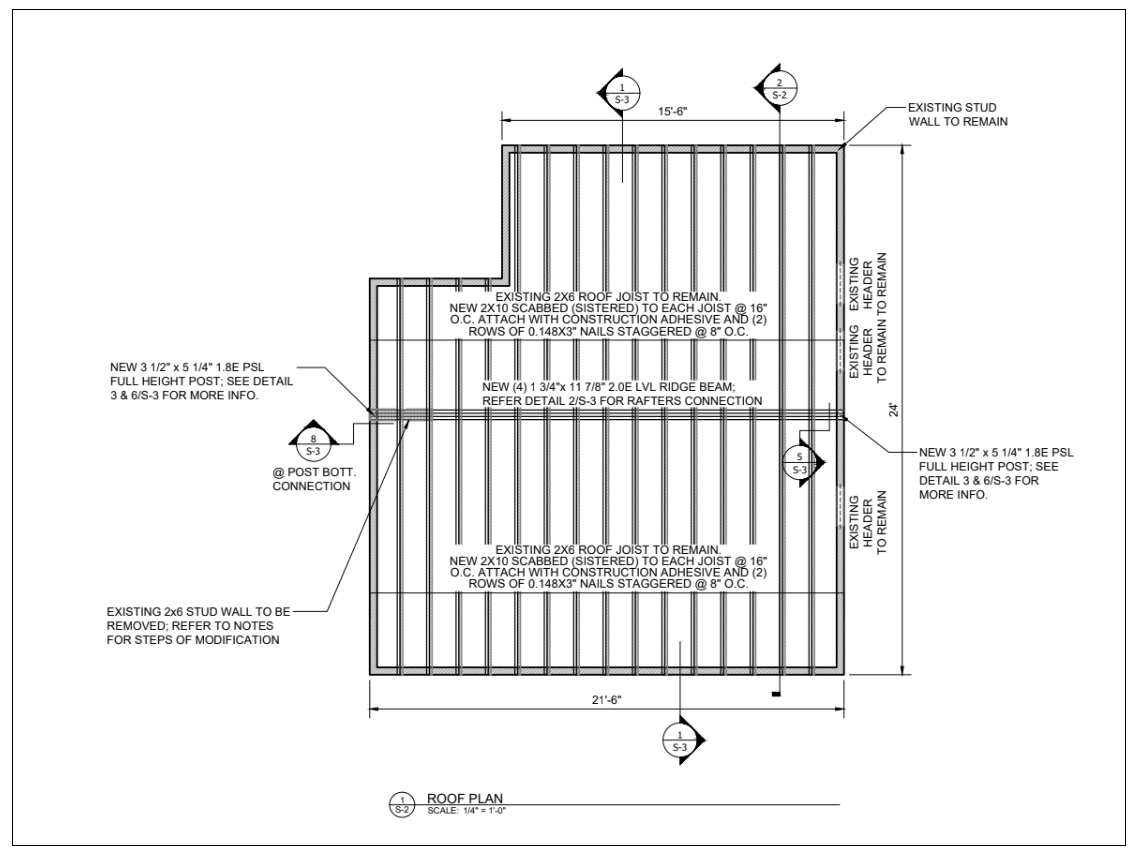

“Many of the older buildings we see weren’t designed with the kind of roof gardens or storm vaults that are common today,” says Anurag Kawale, another senior structural designer at Uppteam. “When these features get added late in the project, they’re often heavier, wetter, and more complex than the original framing anticipated.”

For example, a green roof installed halfway through design might add several inches of saturated soil, which increases both the dead and live loads. That weight travels down through the slab to the columns, which were probably designed under different assumptions. It’s not a minor adjustment — it can rewrite the load path entirely.

When Stormwater Changes the Structure

Every structural designer who’s worked on mixed-use or podium projects has a stormwater story.

In one project in New Jersey, a civil team introduced an underground detention tank after the structural package was nearly done. The tank was meant to hold roughly 30,000 gallons — about the weight of two fully loaded delivery trucks. That much mass, sitting under a slab, changes everything: bending moments, punching shear, deflection, and even connection detailing.

“When you run the numbers, it’s not just a static load,” Harshal recalls. “You’ve got hydrostatic uplift when the tank’s empty, surcharge when it’s full, and movement with temperature changes. Every load case is dynamic, not static.”

It’s a good reminder that what appears as a civil decision — where to put water — often becomes a structural challenge — how to hold it safely.

Similarly, engineers frequently underestimate the impact of pipe routing through beams or slabs. A large-diameter pipe might require coring or openings that interrupt the reinforcement layout. “It looks like a small hole on the plan,” Anurag laughs, “but that little circle can start a domino effect on shear capacity, stiffness, even vibration response.”

These coordination challenges are rarely due to negligence. They happen because the design process itself still runs on legacy silos.

From Silos to Systems: The Integrated Design Mindset

Integrated stormwater–structural design starts with one idea: every drainage path is also a load path.

That means structural engineers need to think hydrologically — understanding how water moves, where it ponds, and how it interacts with the built environment. In turn, civil and MEP designers must think structurally — knowing how loads, deflection, and reinforcement affect the systems they design.

In practical terms, integration looks like:

- Structural designers reviewing stormwater reports early to identify where detention vaults or bio-planters might affect framing.

- Civil engineers are looping structural teams into pipe layout discussions before finalizing slopes or outlet elevations.

- Architects working with both teams to shape podium decks and terraces that manage runoff without stressing the slab below.

It’s a conversation that needs to happen months earlier than it typically does.

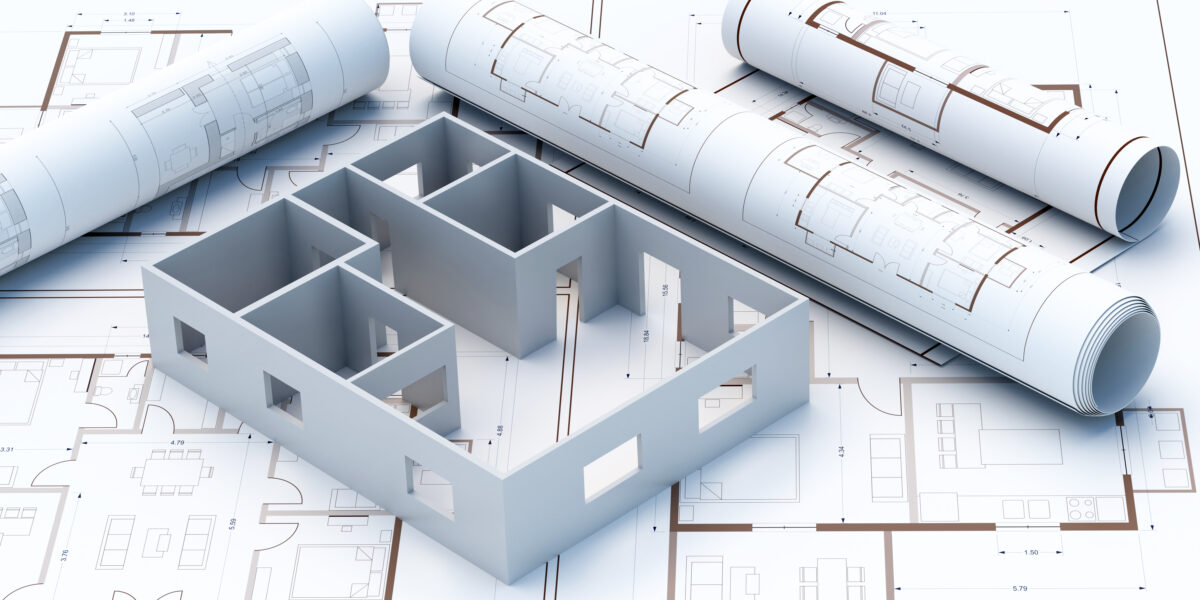

How Modeling Workflows Make It Work

Digital modeling has become the bridge between disciplines. But simply sharing models isn’t enough — the workflows must talk to each other.

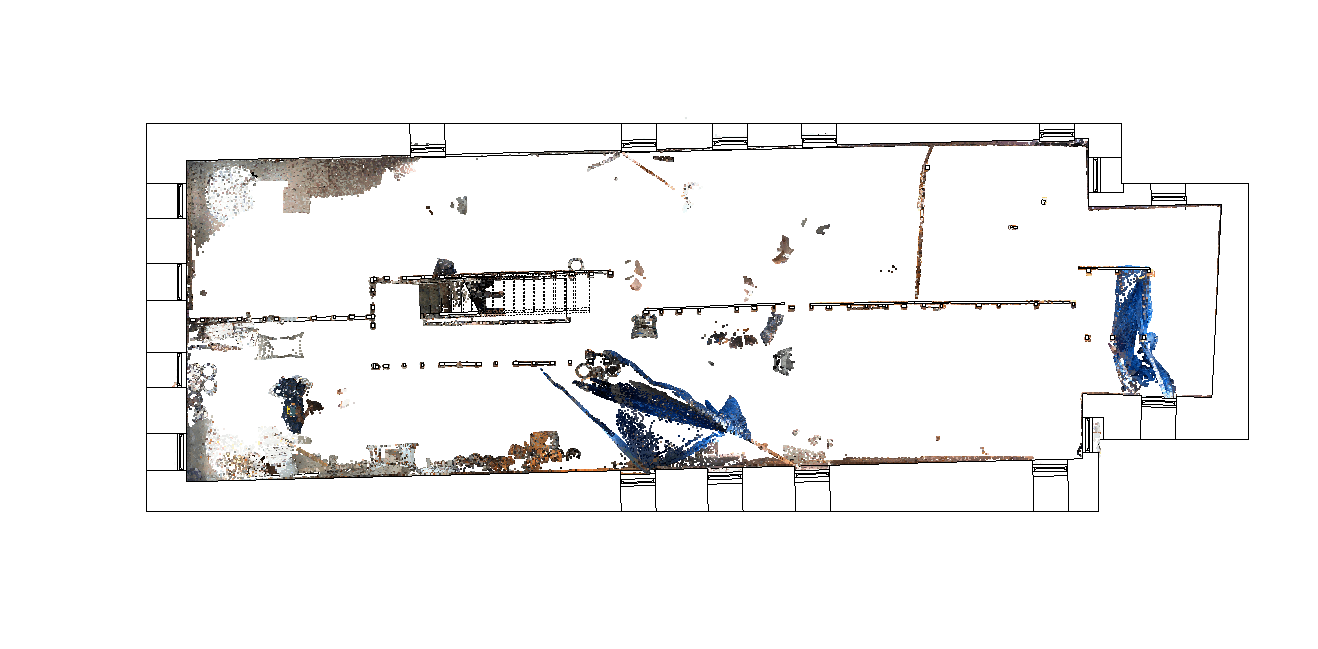

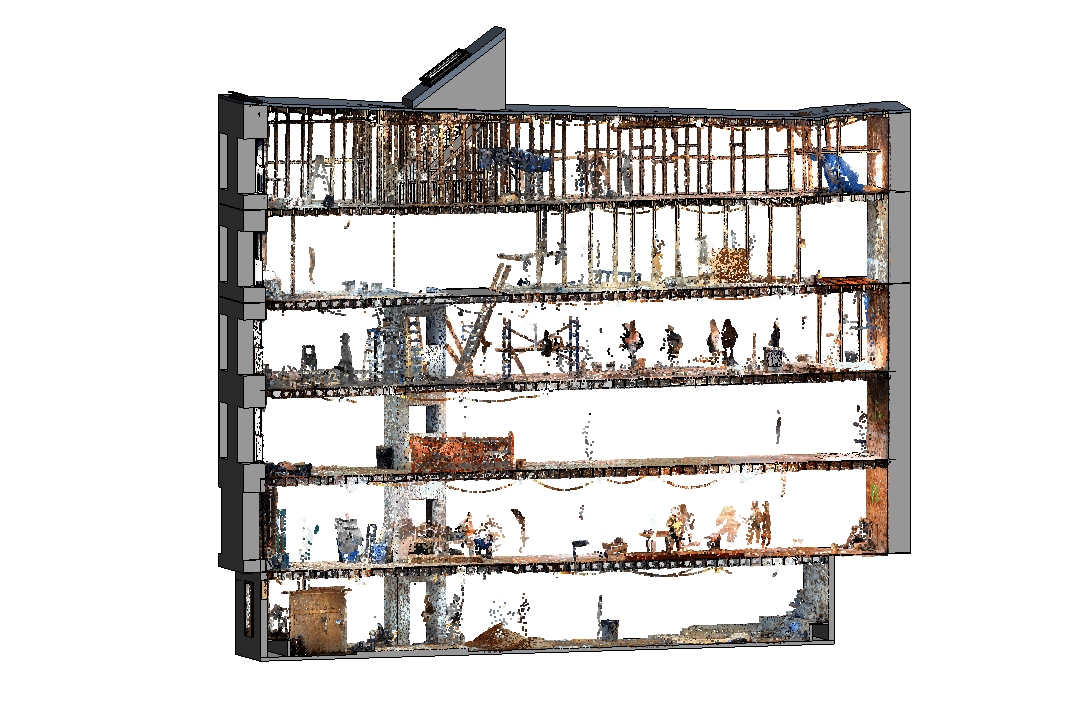

At Uppteam, we’ve seen that coordination succeeds when the BIM environment is used not just for drawing, but for thinking. For instance, in a recent mixed-use development in Texas, our structural team integrated the stormwater model directly into Revit. Instead of treating drainage as background geometry, it was part of the analytical model. That lets engineers simulate the weight of saturated soils, check slab bending under temporary ponding, and visualize pipe penetrations before construction.

It’s the kind of proactive modeling that saves projects from weeks of RFIs.

The real advantage, according to Harshal, isn’t only in avoiding clashes, “When you model stormwater with the structure, you can literally see how water wants to move. That’s when design starts to feel like problem-solving, not firefighting.”

Anurag adds that digital tools help make the invisible visible — “You can explain to a client why a vault location matters or why we’re thickening a slab. It’s not theoretical anymore. The model tells the story.”

Where Codes Leave Off and Practice Begins

American building codes like ASCE 7-22 have improved their coverage of flood and ponding loads, but they’re still a starting point, not an endpoint. The truth is, code compliance doesn’t guarantee durability.

Engineers working in high-precipitation zones often go beyond code by checking secondary load combinations — for example, considering uplift on empty tanks, long-term corrosion cycles, or repeated saturation of concrete in podium decks.

This is where experience shows. As Anurag puts it, “You learn quickly that corrosion doesn’t care about code commentary. If water sits somewhere long enough, it’ll find a way in.”

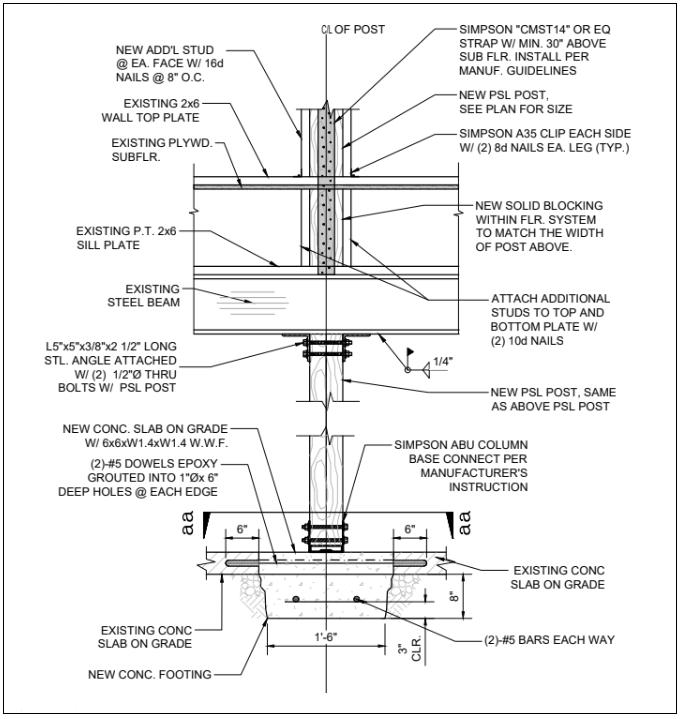

Durability-focused design often involves detailing that looks minor on paper but makes all the difference: specifying protective coatings, ensuring waterproofing continuity at column bases, or providing secondary drainage channels to relieve ponding.

Integration, at its best, is about seeing those details not as “extras,” but as part of the structure’s DNA.

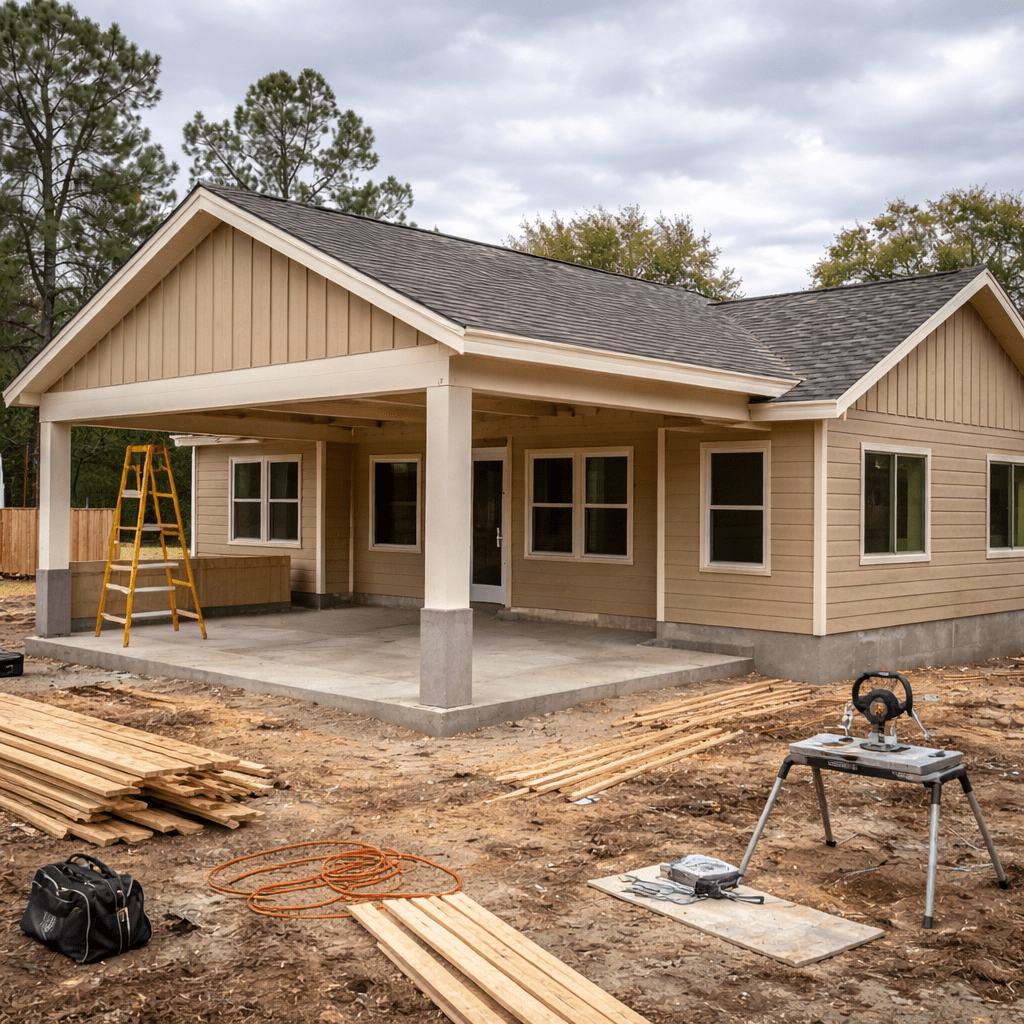

Lessons from the Field

Many of the lessons around integrated design come from retrofit or rework cases.

A structural firm in California had to strengthen an underground garage slab after repeated leakage corroded post-tensioned tendons. The fix involved not just re-tensioning but redesigning the entire drainage path above. Once a proper slope and redundant outlet were introduced, the corrosion stopped progressing. The takeaway was simple: water management is structural protection.

In another case, a civic plaza in Chicago added green planters for sustainability credits — but the added soil depth created new live loads, and the waterproofing membrane wasn’t rated for that exposure. Within two years, cracks appeared along the planter walls. The post-analysis revealed that the membrane had failed due to lateral pressure from saturated soil.

“Those are the quiet lessons that shape how we now design,” says Harshal. “Every time we add weight, add water, or add a hole, the structure wants to tell us something. We just need to listen earlier.”

Why Integration Equals Resilience

Resilient design isn’t just about surviving extreme events — it’s about how gracefully a structure handles everyday stress.

Integrated stormwater and structural design reduces unplanned loads, limits corrosion, and extends service life. It also makes maintenance predictable. When you know where water travels and how it’s supported, inspections become smarter, and failures become rarer.

Cities are beginning to recognize this, too. Los Angeles and Philadelphia now encourage integrated coordination between stormwater and structural systems in their sustainability frameworks. It’s not only good for the environment; it’s suitable for infrastructure budgets.

For U.S. structural firms, adopting this mindset also brings a competitive edge. Clients increasingly expect resilience to be designed in, not added later. Teams that demonstrate coordination between stormwater and structure stand out — they’re not reacting to problems; they’re preventing them.

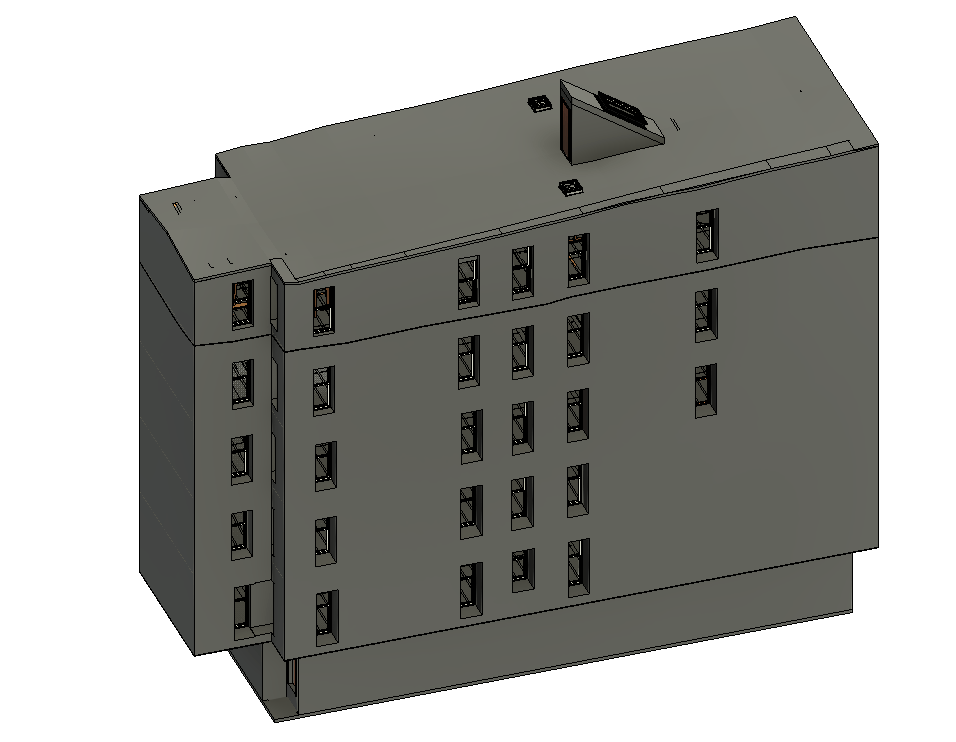

The Uppteam Perspective

Uppteam’s design support philosophy has always centered around integration before iteration. Our designers work with U.S. engineering firms to develop BIM-based structural models that anticipate real-world challenges — including stormwater interaction, drainage loads, and long-term durability.

What sets our structural support apart isn’t just accuracy — it’s empathy for how design decisions play out on site. Harshal often describes it as “thinking like a contractor before you even finish the drawings.”

By helping firms align stormwater and structural systems early, Uppteam bridges the traditional gap between design intent and construction reality. Whether it’s modeling detention vaults under slabs, coordinating pipe penetrations, or creating construction-ready drawings that embed both load data and hydraulic behavior, our goal is simple: to help engineers design structures that last longer, perform better, and adapt faster.

Conclusion: Designing With the Storm in Mind

The most resilient urban infrastructure isn’t the one that resists water — it’s the one that understands it.

For structural engineers, that means embracing stormwater as a legitimate design load, not a postscript. It means seeing every vault, drain, and bioswale as part of the structural conversation.

As Harshal said during one recent Uppteam project review, “You can’t design in isolation anymore. The water doesn’t care whose scope it is.”

At Uppteam, the next generation of urban resilience will be built not just on stronger materials, but on smarter coordination. By merging stormwater insight with structural precision, we help firms design buildings that can weather both the storm and the decades that follow.

Because in the end, resilience isn’t about predicting the next flood — it’s about designing for the ones we already know are coming.