Buildings that can survive wildfires are designed very differently from those that burn. In most cases, the main differentiator is the early design and integration of MEP systems.

The U.S. climate is now at a point where architects and general contractors know wildfire resilience is no longer optional. In fact, it is a basic design requirement that requires attention during the planning phase. It should never be an afterthought during construction.

Over the past couple of years, wildfires have become more frequent and intense. One must acknowledge that the expansion of wildland-urban interfaces poses severe risks to the buildings you design and construct.

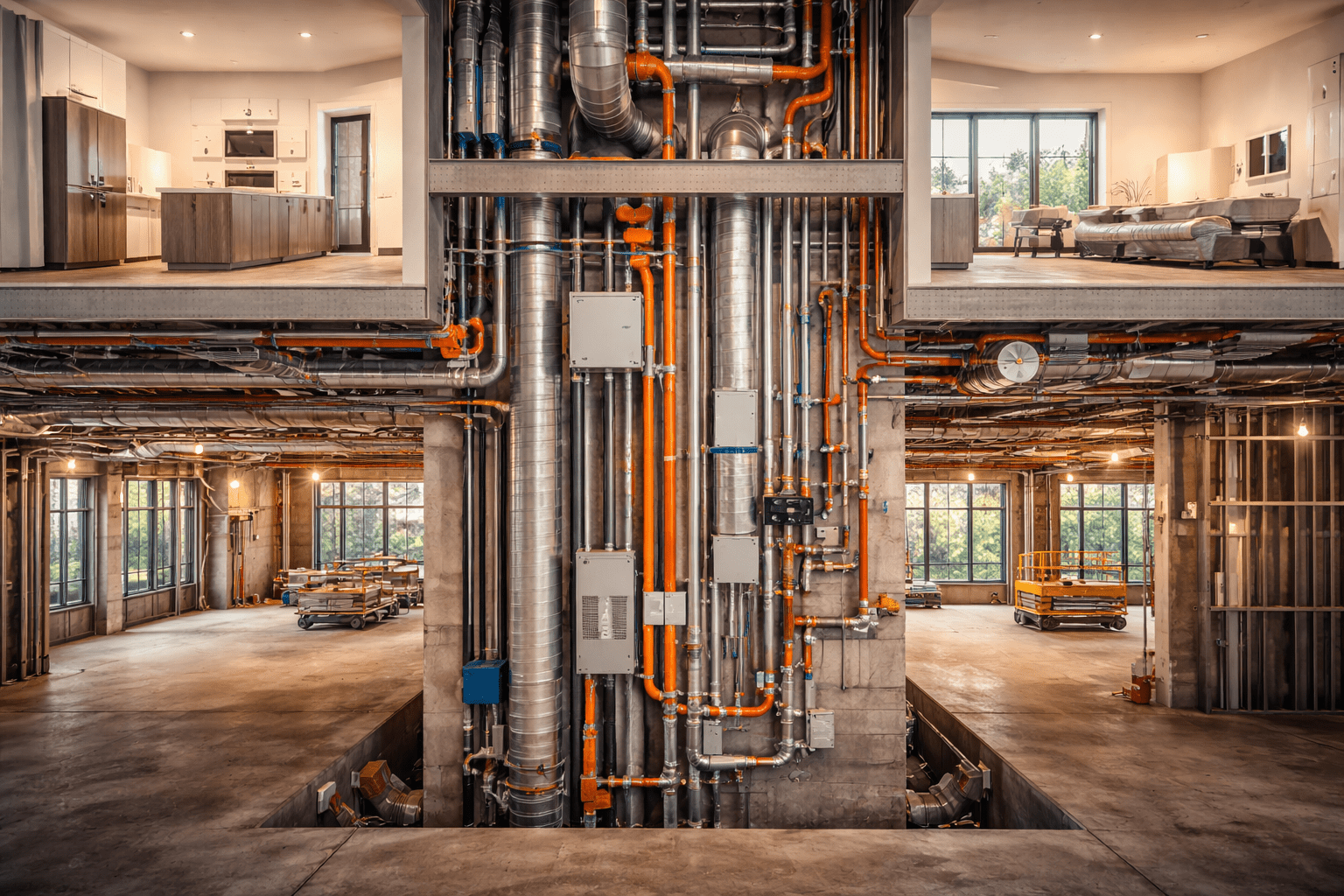

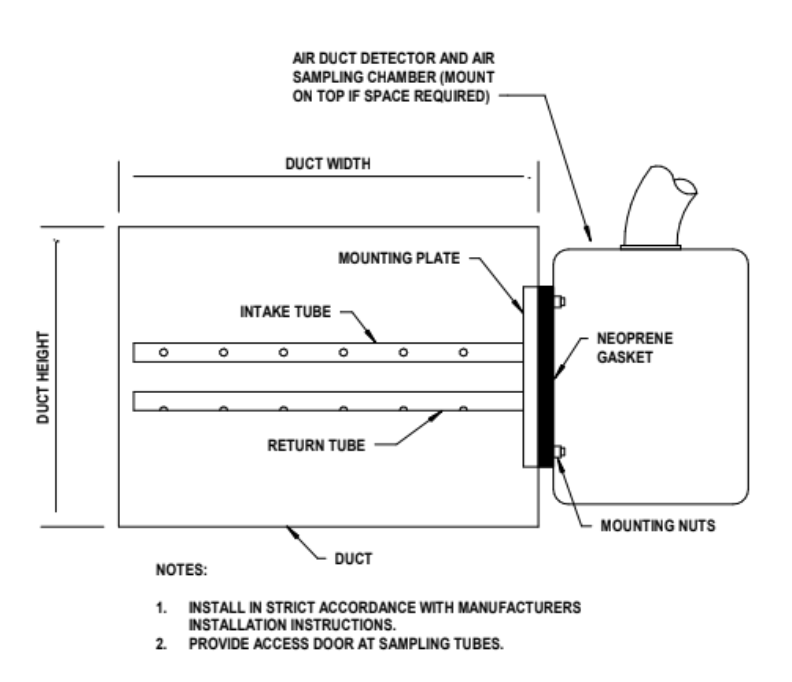

MEP systems can lead to multiple penetrations through fire barriers, allowing flames, embers, and superheated gases to pervade buildings through concealed cavities. Therefore, it is essential to understand how to detail fire-resistant materials, resilient water supplies, and backup power to boost wildfire performance. Such choices help buildings remain functional for occupants and emergency responders during a fire incident.

By addressing these pillars during the MEP design phase, architects and GCs can ensure that projects are in alignment with the latest code requirements while truly safeguarding the communities they serve.

Fire-Resistant Materials: Establishing MEP Foundation

Do you know what the most critical first line of defense for a building against wildfire penetration is? It is none other than your choice of materials throughout MEP systems.

Concrete is known for its outstanding fire resistance, withstanding temperatures up to 400°C, provided there is no structural weakness. This makes concrete perfect for equipment rooms and mechanical areas where heat intensity tends to be at its peak. Likewise, mineral wool insulation can endure temperatures up to 1000°C, delivering even superior performance compared with highly flammable foam products.

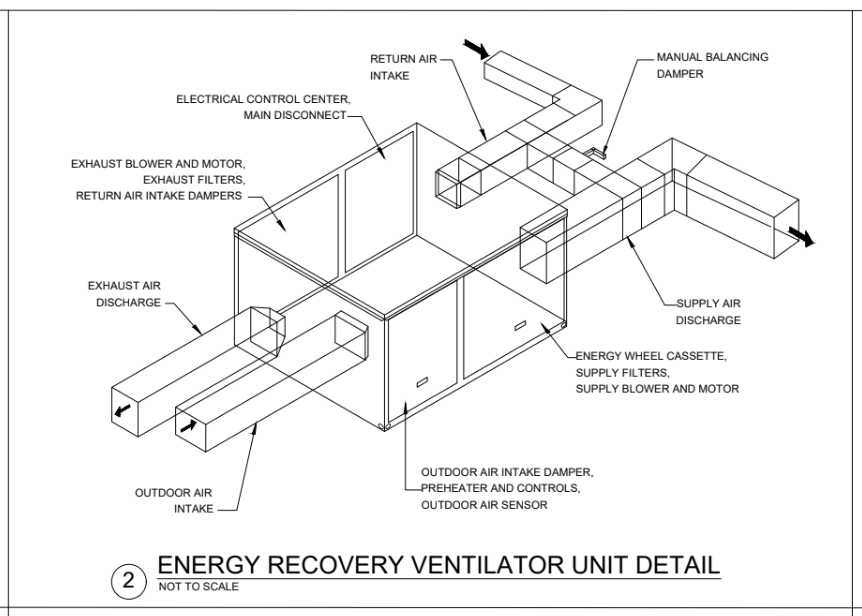

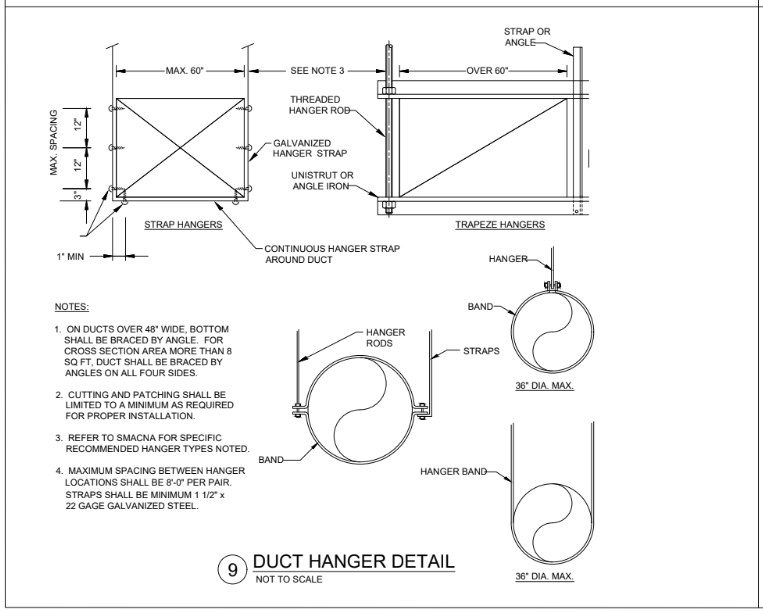

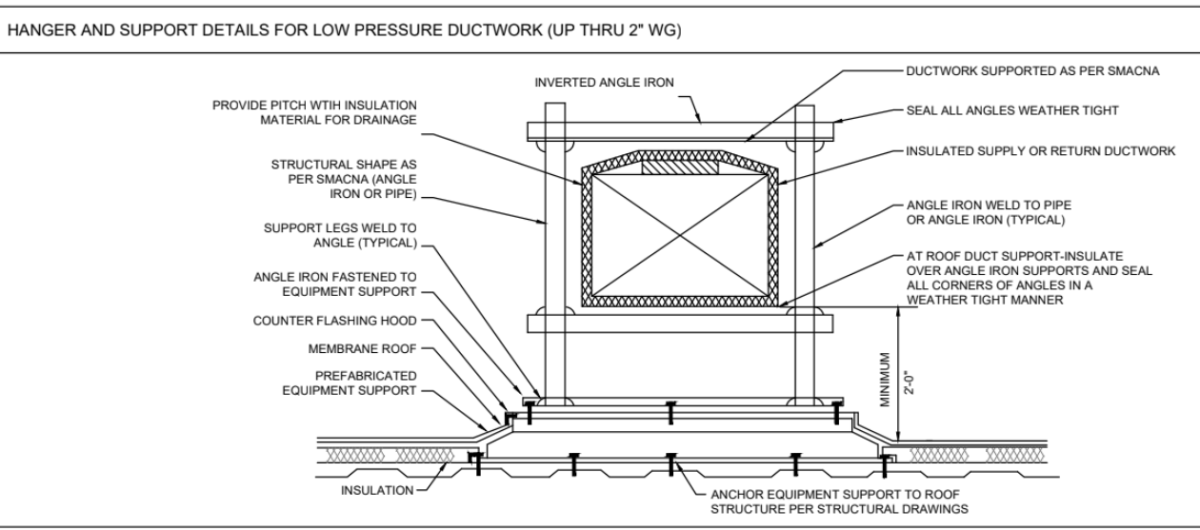

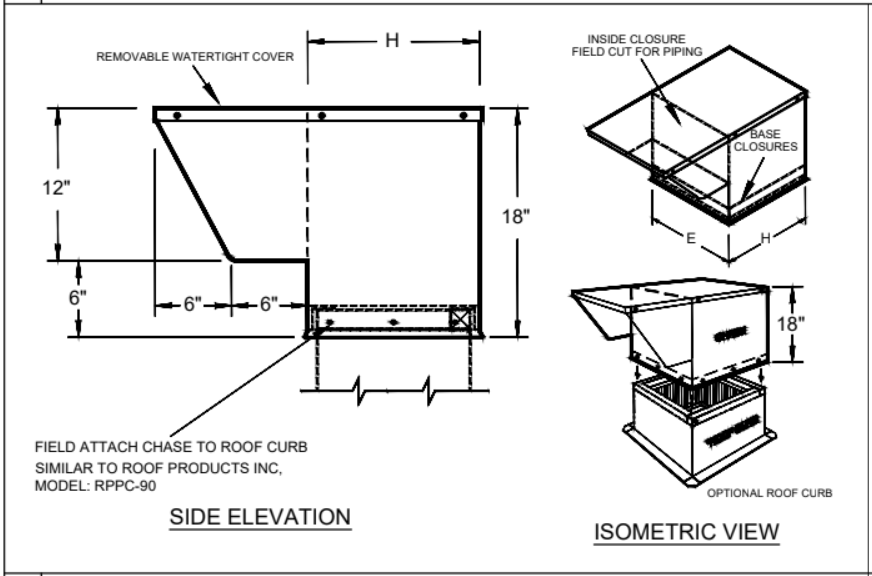

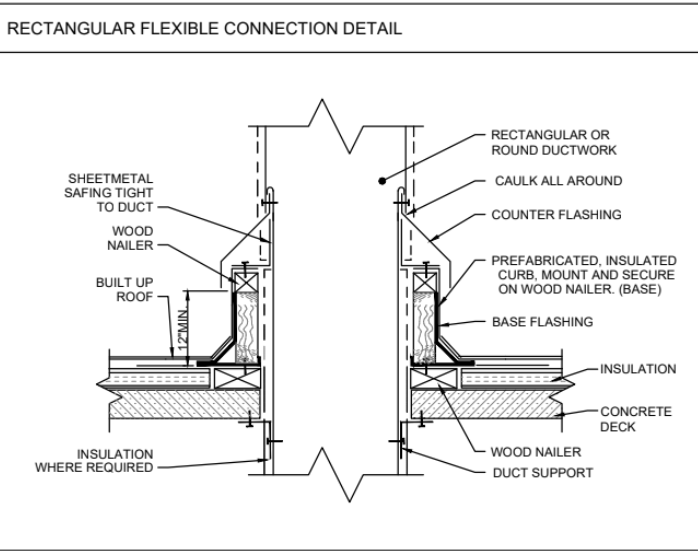

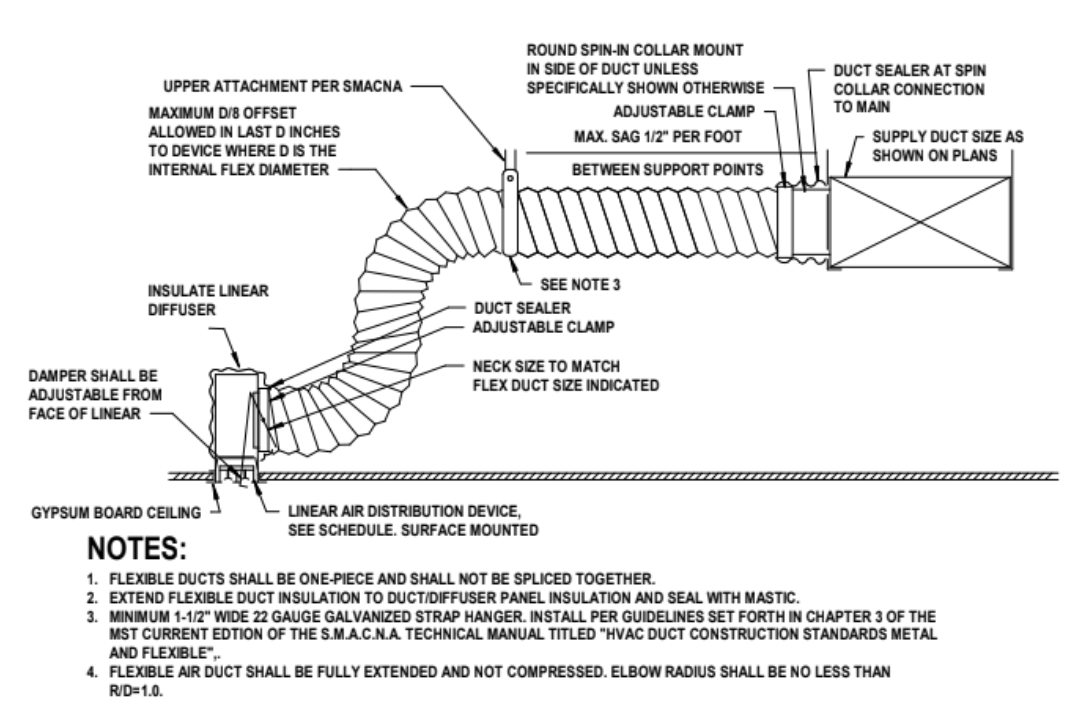

Thus, at the time of specifying ductwork within fire-rated assemblies, it is critical to choose fire-rated sheet metal instead of flexible ducts that melt more easily.

When it comes to electrical systems, a similar level of rigorous attention should be given to material specifications. Fire-rated cables that meet BS EN 50200 certification norms can uphold circuit integrity for up to 2 hours during fires. They provide protection for important systems, such as fire pumps and emergency alarm networks. It is even more important to specify metal conduits and trunking rather than plastic alternatives.

On the other hand, we know that intumescent sealants can expand ten times their original size when heated. Using them can effectively seal gaps around penetrations and stop embers or flames from dispersing via concealed cavities. Keep in mind that these sealants are highly effective at shielding HVAC ducts from fire barriers, helping to restrict fire spread.

Moreover, the installation of intumescent fire dampers at ductwork penetrations is also a great solution. They help prevent hot gases and flames from flowing through HVAC systems into occupied spaces. Dampers have no moving parts that can fail under wildfire conditions.

So, for architects and GCs, ensuring that the designs are always effective by specifying such passive, maintenance-free fire protection aspects is crucial.

Maintaining Suppression Capability Through Water Supply Resilience

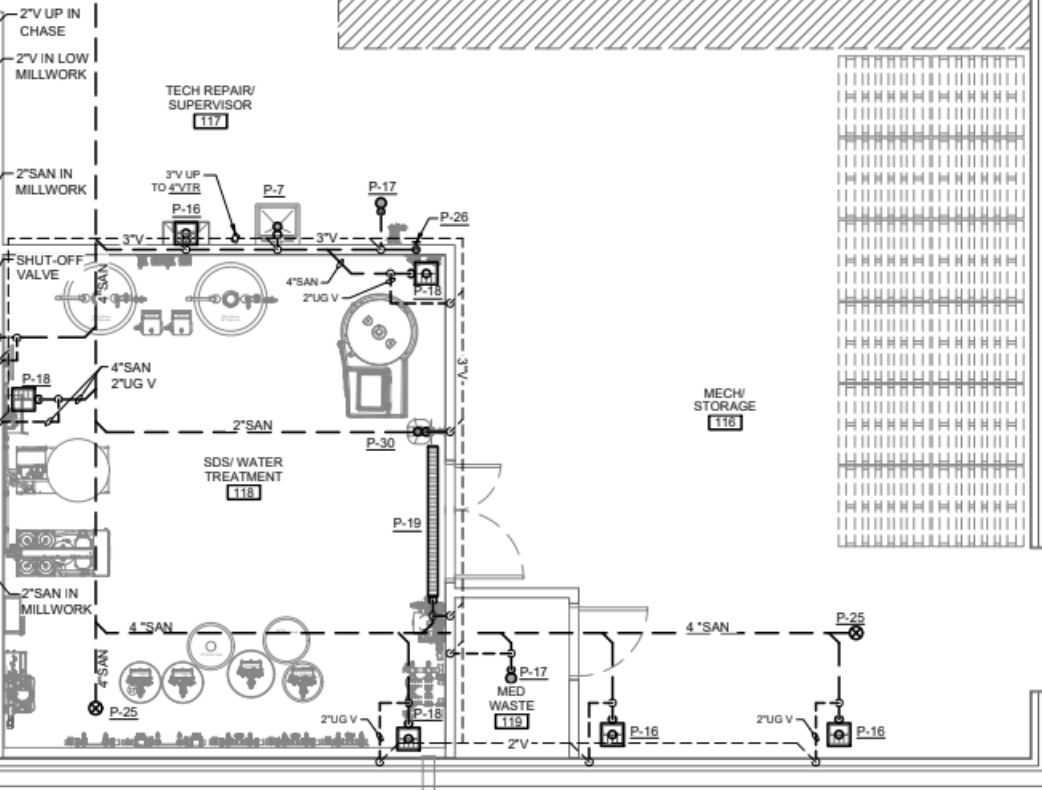

Suppressing fire calls for sufficient pressure and volume. This is particularly relevant in multi-story buildings, where pumping water to higher floors requires advanced engineering coordination.

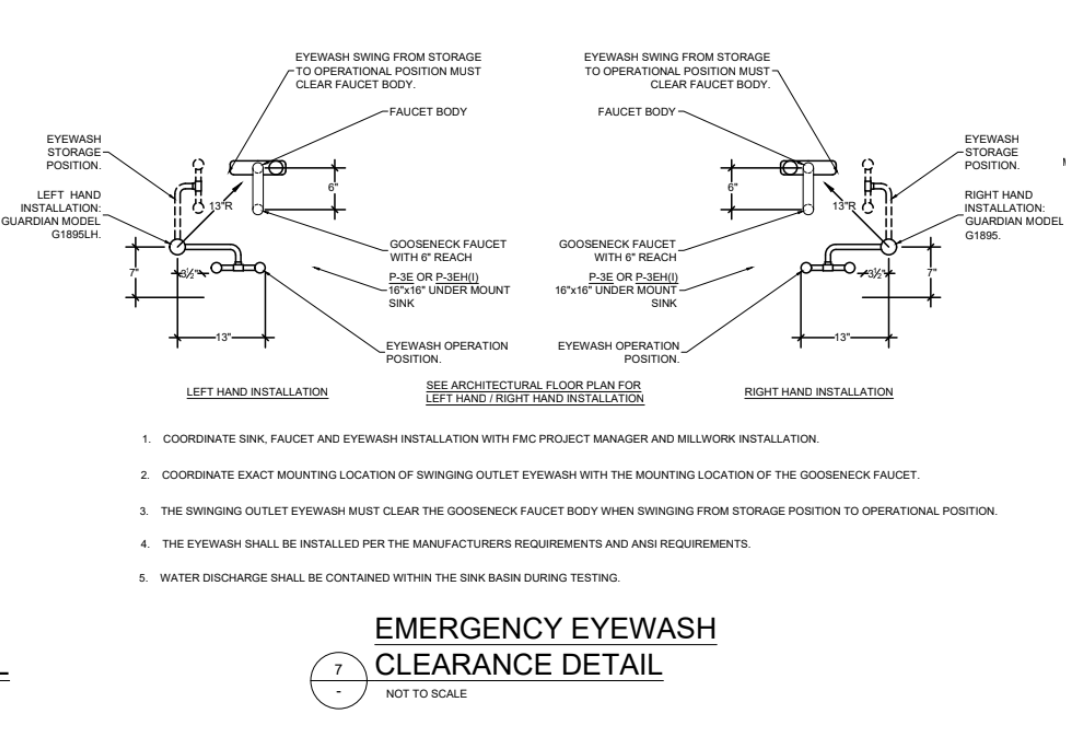

Contemporary building codes necessitate designing plumbing systems that can deliver enough pressure to sprinkler heads at the highest elevations. These systems should provide the recommended force even when utility pressure fluctuates or fails during emergencies.

Architects and GCs must ensure the implementation of the following tactical resilience measures when designing water supply systems in areas prone to wildfires:

- Individual water risers with redundant supply paths avoid single-point failures that could compromise fire suppression throughout the entire building.

- Raised water storage tanks sustain pressure during utility disruptions. This ensures sprinklers function when the central grid becomes unavailable during emergencies.

- Backflow preventers and check valves safeguard municipal supplies from contamination while stopping reverse flow when pressure fluctuates.

- Clearly labeled isolation valves facilitate a rapid response to damage without turning off the entire system.

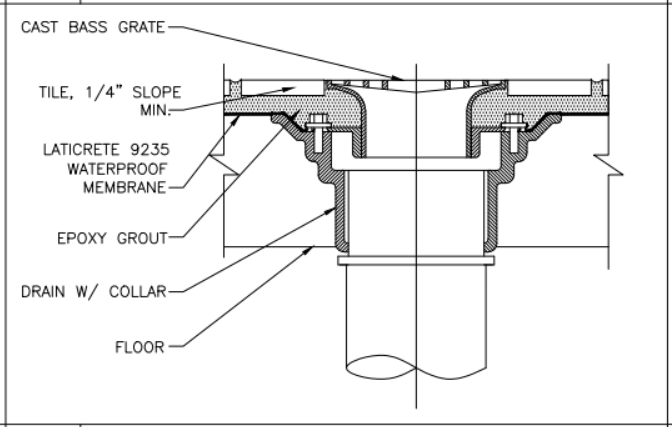

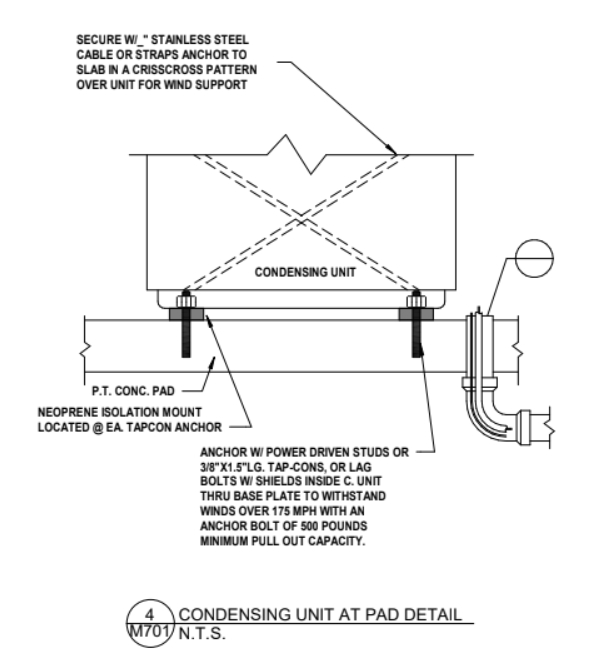

Heat generated from a wildfire can damage plumbing. That is why it is important to insulate and route pipes away from flammable materials. We know that copper and brass conduct heat, making it necessary to add thermal breaks and fire stops. Finally, flexible connections should be prioritized to ensure safe expansion.

Backup Power Systems to Ensure Continued Operations During Grid Failures

In wildfire-prone areas, Public Safety Power Shutoffs are now common. Consequently, communities are left without electricity during extreme fire weather conditions. However, contemporary projects are now implementing microgrids, battery storage systems, or backup generators to at least maintain critical operations during prolonged outages.

Evidently, microgrids with battery storage allow buildings to run in standalone mode when the primary grid disconnects. This makes sure that electricity is supplied to essential systems without relying on external infrastructure. Besides, battery storage solutions, such as Tesla Powerwall systems, can merge with solar arrays to generate sustained power during extended outages. These systems are especially valuable for data centers, healthcare facilities, and critical infrastructure.

Furthermore, permanent propane or natural gas generators are more reliable and safer compared to portable units during wildfires. Accurately installed systems guarantee HVAC pressurization, water pumps, and emergency communications are uninterrupted when utility power fails. As a result, buildings stay functional throughout an emergency fire situation.

MEP Coordination and Clash Detection

Intensive coordination is pivotal to designing fire protection into MEP systems. And, it should start before production drawings. Cutting-edge BIM tools facilitate visualizing sprinkler heads, HVAC ducts, electrical conduits, and plumbing systems interacting within the same spaces. Accordingly, conflicts get spotted when changes are inexpensive. Early clash detection cycles confirm identifying subtle conflicts that conventional drawing reviews mostly miss. The result is the prevention of expensive rework during construction.

Modeling fire protection systems at an ideal level of development demonstrates dimensioned sprinkler layouts with real branch lines and drops instead of generic placeholders. One must understand that this specificity fosters actual conversation during coordination meetings. One can then make concrete decisions with precision.

Bear in mind establishing frozen ceiling zones ahead of releasing construction documents. This ensures that lighting, sprinkler heads, return air grilles, and structural components occupy clearly delineated spaces and there are no overlaps. This level of collaborative approach revolutionizes fire protection from an afterthought into a unified element that takes overall MEP design quality to a whole new level.

Wrapping Up

So, eventually, wildfire resilience through smart MEP design demonstrates a notable shift in how architects and GCs deal with building systems in fire-prone regions. Recent years’ fire incidents have signified conclusively that conventional MEP design techniques are not enough when intense heat, embers, and smoke penetrate buildings via ignored infiltrations and unprotected connections.

The secrets are designing enduring water supplies, specifying fire-resistant materials, and incorporating backup power systems. Through these approaches, you can create buildings that truly safeguard occupants while sustaining critical operations during emergency circumstances. These design choices made during the MEP planning stage cost way less than retrofitting failed systems after fires destroy communities.

Delivering niche, robust MEP design services is the main forte of National MEP Engineers. Our experts integrate fire safety at the outset of design phases, averting expensive rework and assuring flawless coordination throughout building systems. By blending thorough engineering proficiency with real-world field knowledge of how wildfires realistically behave, we deliver designs that balance energy efficiency, fire protection, and water resilience without compromise.