In the AEC world, the most expensive mistakes are often the ones no one sees coming. A duct routed through a beam. A structural grid that doesn't quite line up. A specification that contradicts itself in two different places.

On paper, these seem small. On site, they can trigger ripple effects worth thousands — sometimes millions — once construction begins.

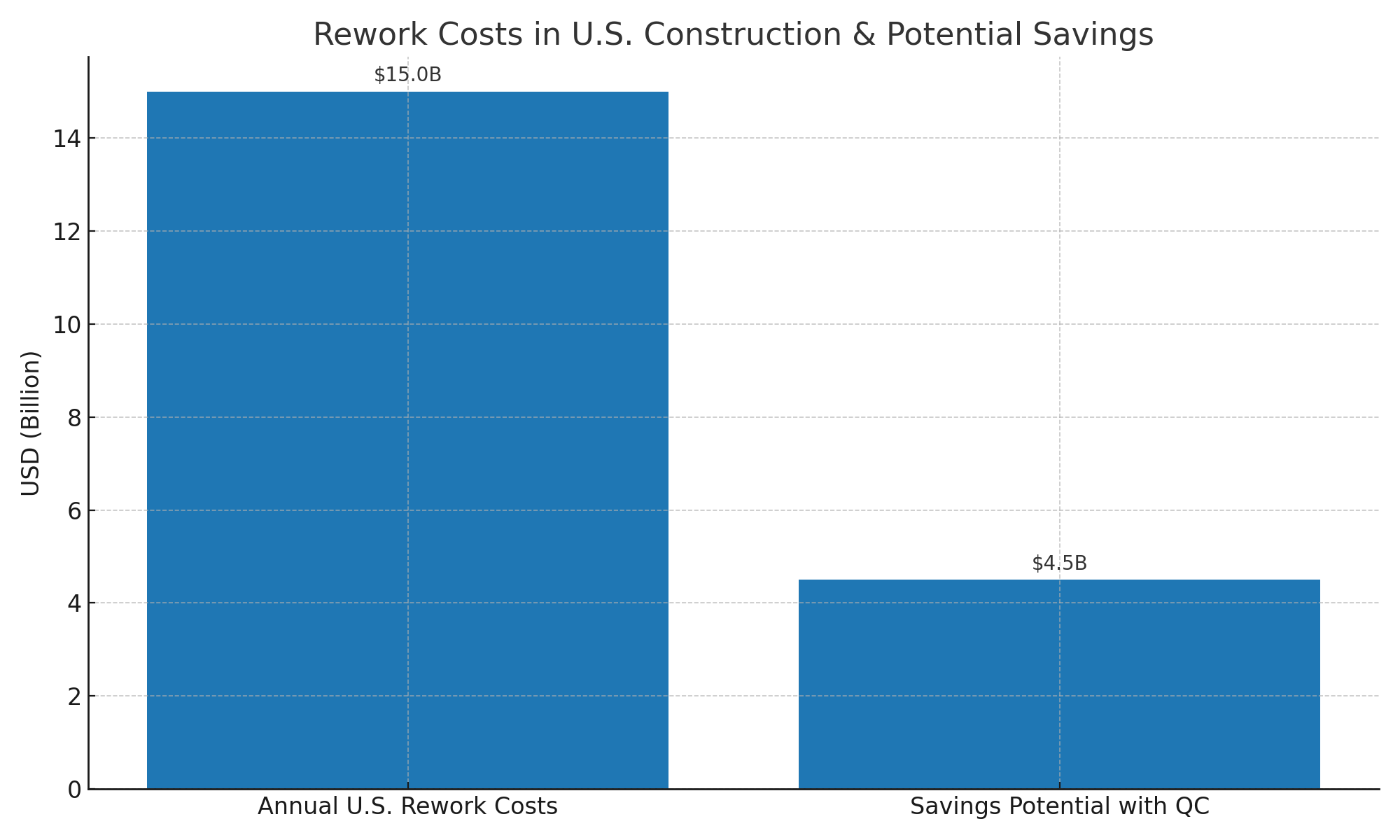

Industry research makes the scale clear. The rework costs in the U.S. construction sector, according to the Construction Industry Institute, are estimated at over $15 billion annually. And that's not just the obvious labor costs and materials. It's missed milestones, frustrated clients, change orders, and reputational damage that lingers long after the ribbon-cutting.

What makes these losses especially painful is how preventable many of them are. A Request for Information (RFI) that costs $50 to resolve in design can balloon to $500 or more once construction starts. A coordination conflict that takes an hour to fix in the model might require days of demolition and rework in the field.

Most of these issues don't arrive with flashing warning lights. They hide quietly, as a mismatched annotation here, a single uncoordinated drawing there, until they cause a chain reaction of delays.

The Hidden Costs Beyond the Obvious

Material and labor overruns are only part of the story. The ripple effects can be equally harmful and often more challenging to recover from..

- Schedule Delays – When structural steel arrives but can't be installed due to MEP conflicts, the entire project timeline shifts. Subcontractors drift to other jobs, and bringing them back can mean premium rates.

- Change Order Administration – Each change order isn't just the direct cost. Processing it can eat $1,000–$3,000 in admin time across architects, owners, and contractors.

- Client Relations – Unexpected expenses and hold-ups diminish trust. Design firms risk losing repeat clients. Contractors risk slimmer margins and potential claims.

- Legal Liability – In severe cases, coordination errors can lead to safety or structural failures, opening the door to litigation far exceeding the original project value.

- Insurance Impacts – Frequent claims drive up professional liability premiums, adding cost pressure on every future job.

These hidden costs are why proactive error detection isn't just about the current project — it's about safeguarding the business.

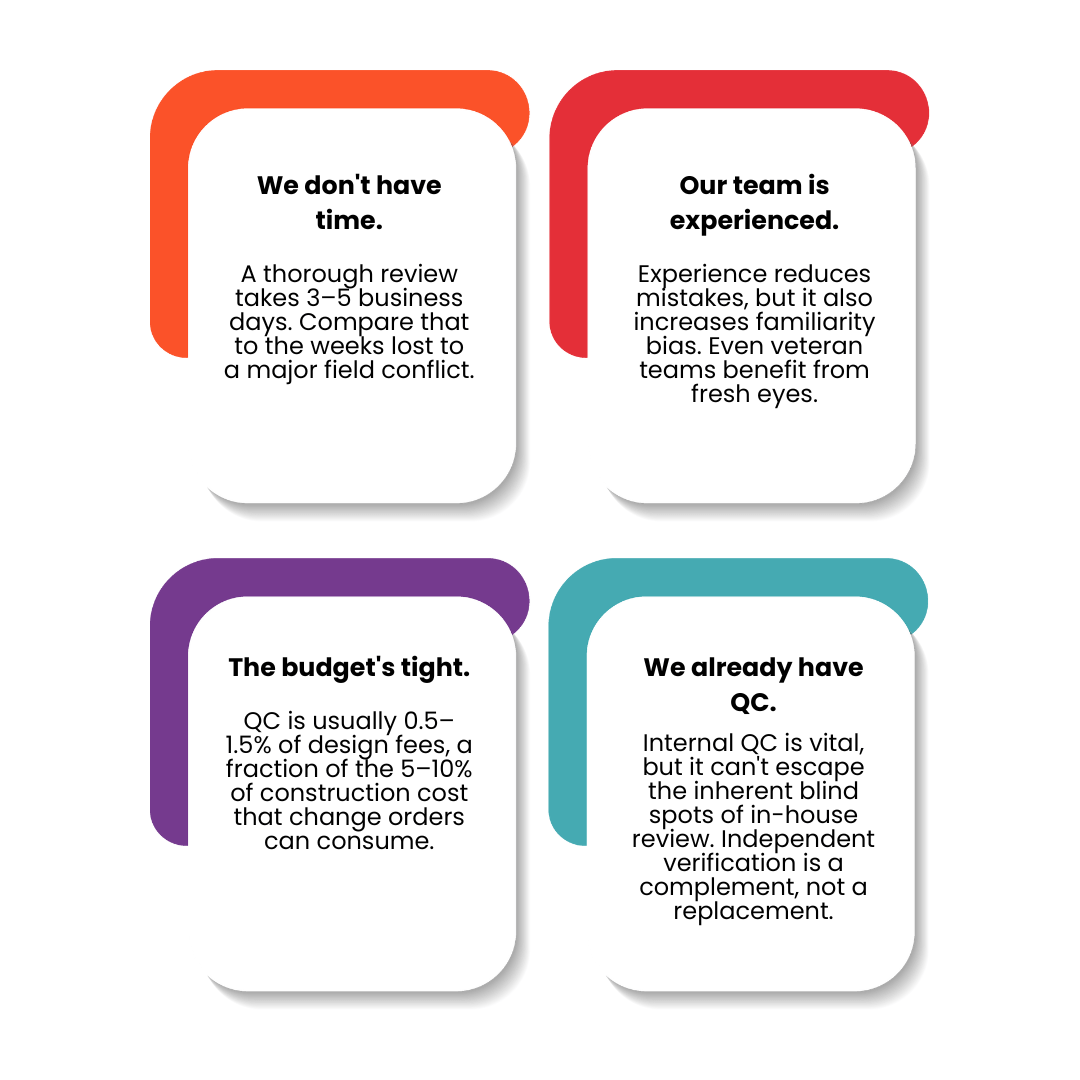

Why Internal Reviews Still Miss Things

Every design team runs QA/QC. The challenge isn't lack of effort or expertise — it's the human and operational limitations baked into the process.

When you've worked on a set of drawings for weeks or months, familiarity bias kicks in. You see what you expect to see, not what's there. That duct "must" clear the beam because that's how you designed it.

Then there's deadline compression. Reviews that should be methodical turn into quick passes, often just to check the box. And team dynamics matter: junior staff may hesitate to challenge senior designers, while principals frequently focus on the big picture rather than detailed coordination.

A third-party QC team comes in without any of those blind spots. They have no attachment to specific design decisions, no schedule-driven reason to let something slide, and a singular focus is to find the issues before they cost you.

The ROI Reality Check

Consider this typical scenario.

A third-party QC review costs $5,000 and catches a major MEP/structural conflict. Resolving it during construction would have meant:

- Engineering redesign: $3,000

- Demolition of completed work: $8,000

- Material waste and reordering: $12,000

- Schedule delay costs: $15,000

- Change order administration: $2,000

That's a $40,000 problem avoided — an 800% return on QC investment.

Even small catches add up. We've seen a $2,000 review uncover specification inconsistencies that would have cost $25,000 in reorders and installation delays — a 1,250% ROI from a single phase review.

Real Issues, Real Savings

On a large commercial build, we found a duct run intersecting with a structural beam during coordination review. The design team had been working from an outdated model; the conflict wasn't visible in their workflow. If built as drawn, it would have cost $25,000 in rework and a week of schedule delay.

On another project, we caught a building core shift that wasn't reflected on all drawing sheets. Architectural plans showed the new location, but MEP still used the old coordinates, a mismatch that could have triggered $50,000+ in trade conflicts.

And in a healthcare facility, our team flagged conflicting fire-rated door specs: 90-minute in one set, 60-minute in another. The correction happened before orders went out, preventing reorders, delays, and a change order battle.

None of these errors was about competence. They were the natural result of busy teams working under pressure.

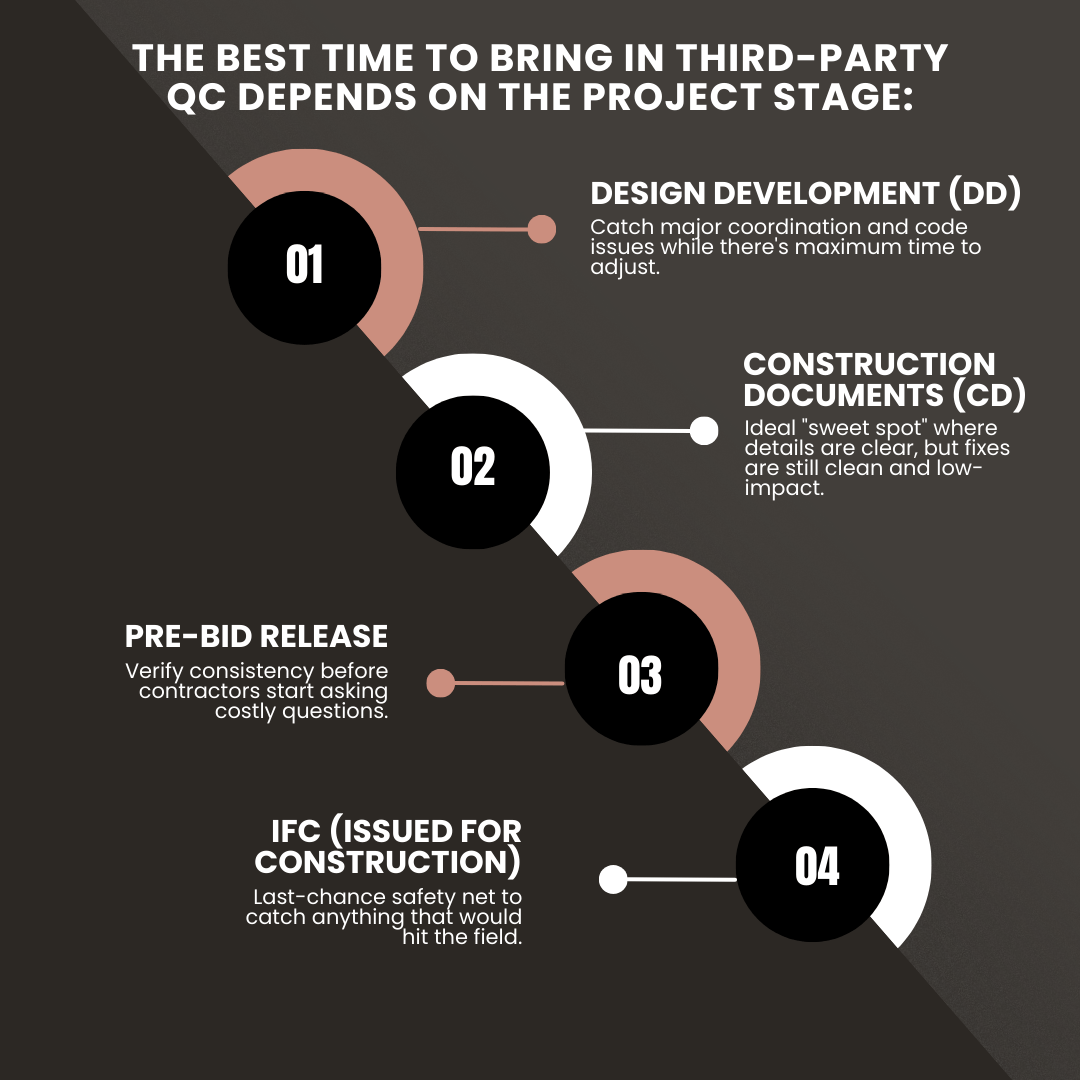

When QC Delivers Maximum Value

While QC is applicable at any stage, CD reviews consistently deliver the best return, providing enough detail to reveal conflicts early enough to fix without disruption.

Addressing Common Pushbacks

How Uppteam Fits In

Our QC service integrates into your workflow without creating bottlenecks. We start by clarifying stage, scope, and priorities — whether that's schematic, CDs, or IFCs.

Our reviews check drawings and models for:

- Coordination and constructability

- Code compliance

- Specification consistency

- Alignment with design intent

Observations are recorded with visual annotations, organized by level of severity, and accompanied by actionable solutions. That way, your team knows exactly where to focus first.

Typical reviews take 3–5 business days, with expedited options when the clock's ticking.

The Long Game: Sustainable Quality

Independent QC isn't just a project safeguard — it's a business strategy. Over time, it leads to:

- Fewer RFIs, freeing project managers to focus on design leadership.

- Reduced change orders, protecting profit margins.

- Stronger client relationships through smoother delivery.

- Lower liability risk and insurance costs.

- Better-trained teams through feedback loops.

It also frees your best people from spending days hunting for coordination issues, letting them focus on high-value creative work.

A Smarter Second Look

Whether you're preparing your first DD set or releasing IFCs, an independent review can be the difference between a project that glides through construction and one that limps to completion.

The question isn't whether your team is capable. It's whether you can afford to rely solely on internal checks when the stakes are this high.

At Uppteam, our role isn't to point fingers. It's to make sure your drawings are right the first time so your build stays on track, your client stays happy, and your reputation stays intact.

In this industry, the cheapest problem is the one you never have to solve.